Product Background Story

In September 2017, in Australia, we found that nylon easily absorbed moisture from the air when printing, causing printing failures. Then, in December, we found the same problem again in PLA and ABS. The materials became brittle after being exposed to the air for 3 months, so we came up with the idea of making our own material dryer. In April 2019, our team moved to Shenzhen, China, where the humidity is very high. We found that the material was more likely to absorb moisture and could no longer be printed, so we made the first prototype. Between May and October, we sent our DIY machine to several friends in the 3D printing industry. They all showed great interest and wanted to see our final product. After researching for a large number of users who own FDM printers, we found that most of them needed a material dryer.

In April 2020, EIBOS began to develop a cost-effective and effective wire dryer. In the following month, we conducted thousands of research and tests before launching our first machine. In July 2020, we manufactured 30 machines and sent them to some 3D printing users or enthusiasts around the world to collect suggestions and feedback. Based on these suggestions and feedback, we developed the final product and decided to launch them on Kickstarter in September. It is the CYCLOPES in front of us. In October 2020, we completed mass production. So far, the excellent performance of CYCLOPES has enabled us to gain the support of a large number of 3D printing enthusiasts, which has prompted us to be more determined in our direction and start the research and development of the second-generation eibos wire dryer Easdry.

Resurrect your filament and unleash your creative potential!

Highlight Key Features

-

360° automatic rotating heating

-

Multiple hot air outlet design

-

Using PTC heating components

-

Multi-material drying

-

Shell made of V0 fireproof material.

-

Automatic humidity control function

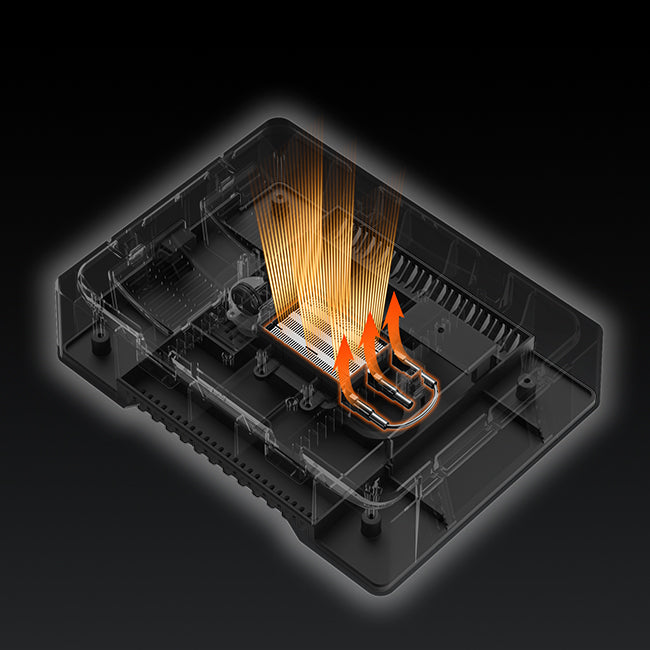

Every filament enjoys uniform temperature

Polyphemus is equipped with an advanced rotating motor that can achieve 360° automatic rotation and heating, ensuring that every corner is evenly heated. With this design, the temperature difference between parts is only 1°C, which means consistent drying results no matter where the filament is located. This uniform heating not only improves the performance of 3D printing materials, but also significantly improves the quality and stability of printed works. By ensuring the material is in optimal condition before printing.

Multiple hot air outlet design

Directing the hot air from the heating element to the filament may cause overheating and uneven heating, which will affect the print quality and material properties. Polyphemus has successfully solved this problem by adopting an innovative design with multiple hot air outlets to ensure that the hot air can be evenly distributed throughout the space. This uniform hot air distribution not only improves heating efficiency, but also greatly enhances safety and protects the integrity of the filament, so that every print can achieve the best results.

Using PTC heating components

Polyphemus uses an efficient PTC heating element, the internal temperature can quickly reach 200 degrees Celsius, which can quickly and stably provide heat, effectively dry the filament, and ensure that it is always in the best condition. This heating technology not only improves drying efficiency, but also achieves the ideal temperature in a shorter time, thus reducing waiting time. At the same time, the PTC heating element has a self-adjusting temperature control function, which can monitor and adjust the temperature in real time to avoid the risk of overheating. This design significantly improves the safety of the device, reduces failure or damage due to overheating, extends the service life of the device, and enables users to use Polyphemus for high-quality 3D printing with greater confidence.

Multi-material drying

The program has built-in baking parameters for 9 commonly used 3D printing materials, including PLA, ABS, PA, PC, PETG, ASA, PVA, TPU and PP, ensuring that users can easily choose the material that suits their printing needs. In order to further meet personalized needs, the system also provides 3 customizable material slots (M1, M2, M3), users can modify the baking parameters according to the requirements of specific materials, and the system will automatically remember these settings for quick call-up next time, saving time and energy. This flexibility allows Polyphemus to adapt to the characteristics of different materials, helping users optimize the drying process and ensure that each material can achieve the best printing effect, thereby improving the overall printing quality and stability. Whether it is a novice or a professional user, you can get a more ideal printing experience with the help of this intelligent system.

Shell made of V0 fireproof material.

All housings are made of the highest fireproof grade V0 material, which has excellent heat resistance and flame suppression performance, ensuring safety and reliability in high temperature environments. This material has been rigorously tested to effectively resist the spread of flames and reduce the risk of accidents, thus providing additional safety for users. In addition, the durability of V0 grade materials allows Polyphemus to maintain excellent performance in long-term use and adapt to various working conditions. Whether it is a high-temperature printing environment or long-term continuous use.

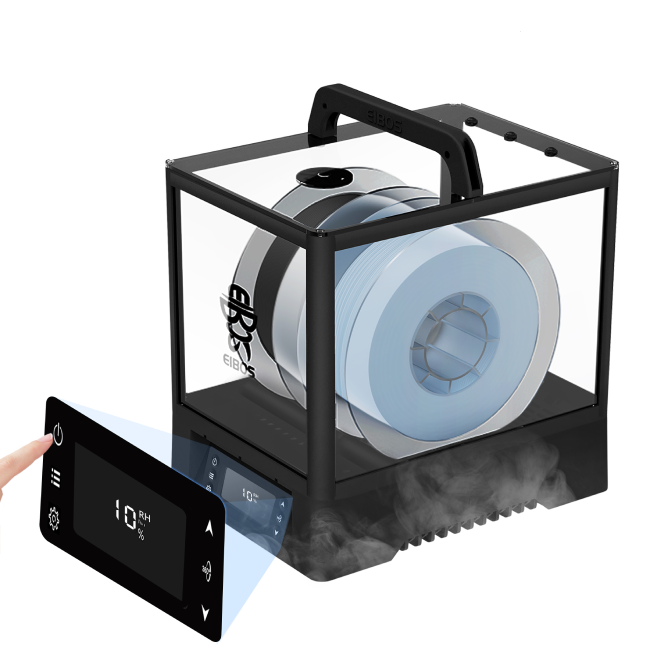

Automatic humidity control function

When heating is not required, users can enable humidity mode and freely set the target humidity to ensure that the consumables always maintain the best printing state. The system will intelligently monitor and adjust the ambient humidity, automatically control air circulation and dryness, and effectively avoid the impact of moisture on material quality. This intelligent control can not only prevent printing failures caused by moisture absorption of materials, but also extend the service life of consumables, ensuring that every print can achieve the desired effect.

Using Polyphemus showcases its outstanding performance.

When you use Polyphemus, you will feel its excellent performance. The best performing filament dryer of 2024.

What's in box?

How to install?