Story

We are EIBOS, a start up 3D printing company, was founded in 2020. Kickstarter is where we started. Our first product EIBOS Filament Dryer Cyclopes launched on Kickstarter at September 24, 2020 and was supported by 1339 users. Although we only had limited conditions and resources at that time, we completed the delivery on time and strictly abided by the rules of the platform - no sales on any other platform until the Kickstarter Backer receives the goods. As a young company, we are grateful to those who initially supported us through Kickstarter. We are nothing without your help and support. The following year we launched our single roll filament dryer Series X: Easdry. We firmly believe that active drying and external circulation are the basic methods that an effective 3D printing filament dryer should using. This may be different from or contrary to the mainstream filament drying methods on the market at that time, but we are still firm in our way. Just like our name EIBOS, we believe in structure, experiments, and data. We hope that through our research and exploration we can create products that can truly help users. This is our original intention, and we have never changed this view and attitude. At present, in the 3D printing industry, even those large companies and skyscrapers are trying to use our original ideas and designs to develop their similar products. This is a great recognition for us. As the first 3D printing filament dryer manufacturer on the market to use PTC as the heating element, we have collected a large amount of information and data on filament drying and drying equipment, which also includes our analysis of user usage. After nearly a year and a half of development and testing, we are here to officially launch our new generation of filament dryers: Polyphemus

We believe that the next generation of drying machines should have these key elements:

After 3 years of accumulation and feedback from supporters, we developed a new generation of filament dryer.

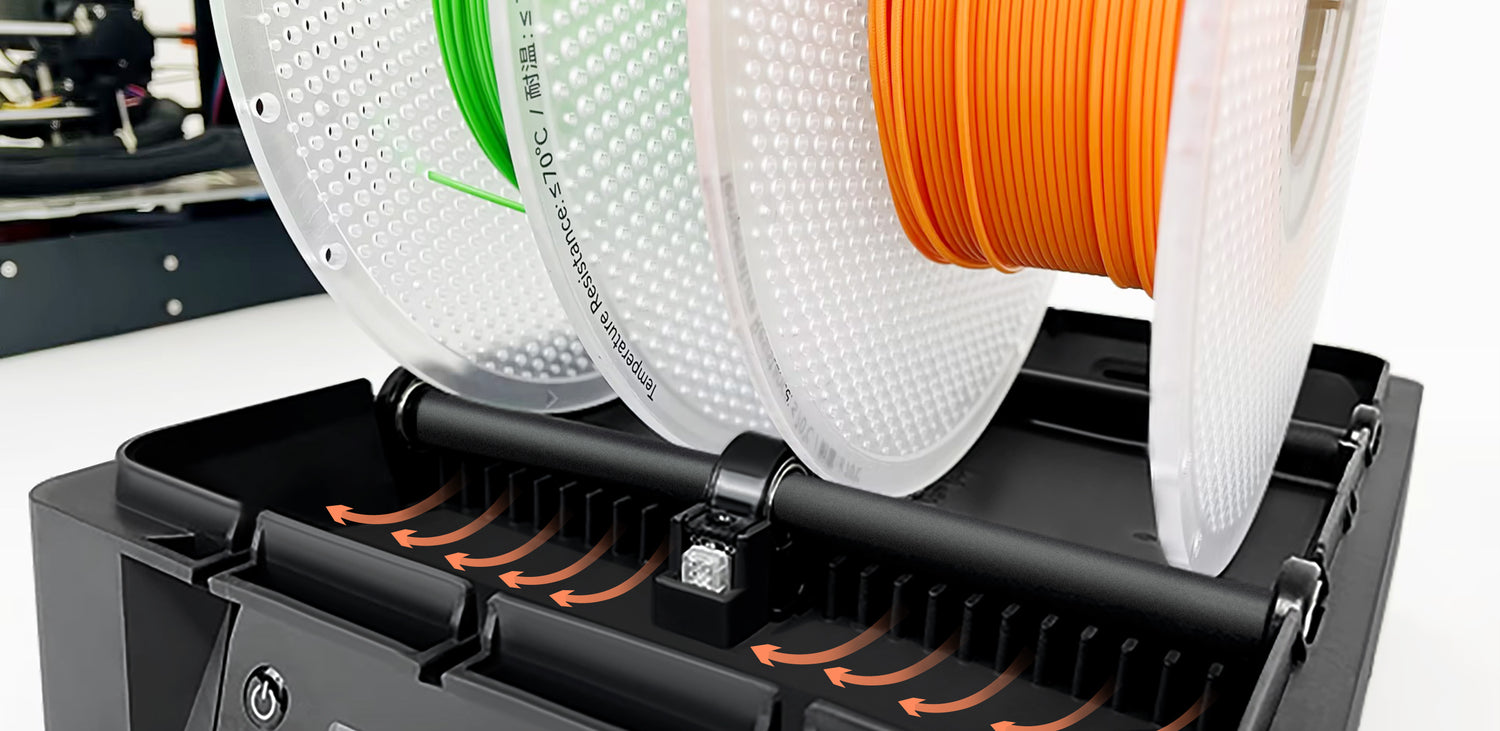

Directly blowing hot air from the heating element onto the filament may result in excessively high temperatures and uneven heating. Polyphemus addresses this concern by incorporating multiple hot air outlets, ensuring that the hot air does not directly blow onto the filament.

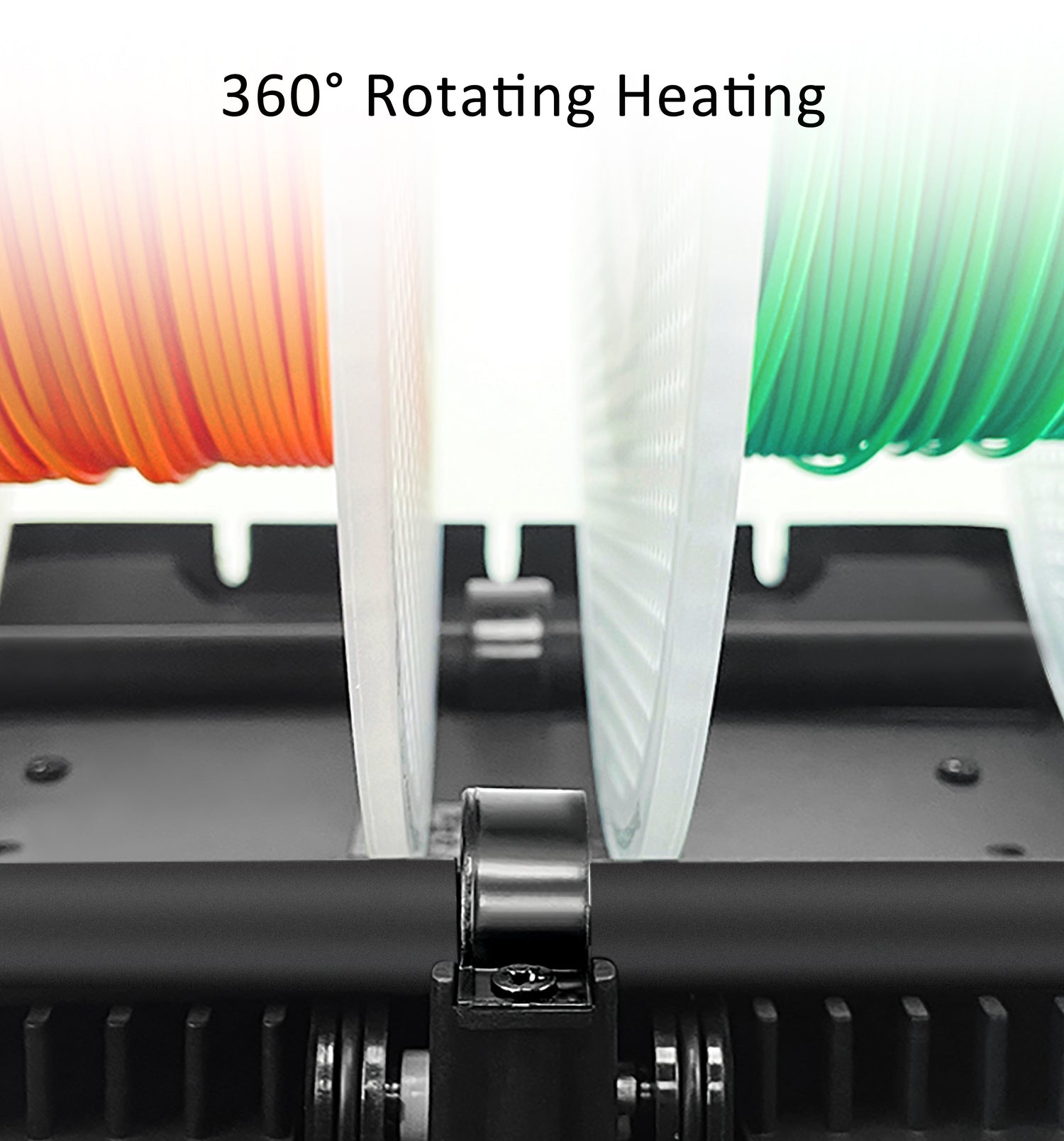

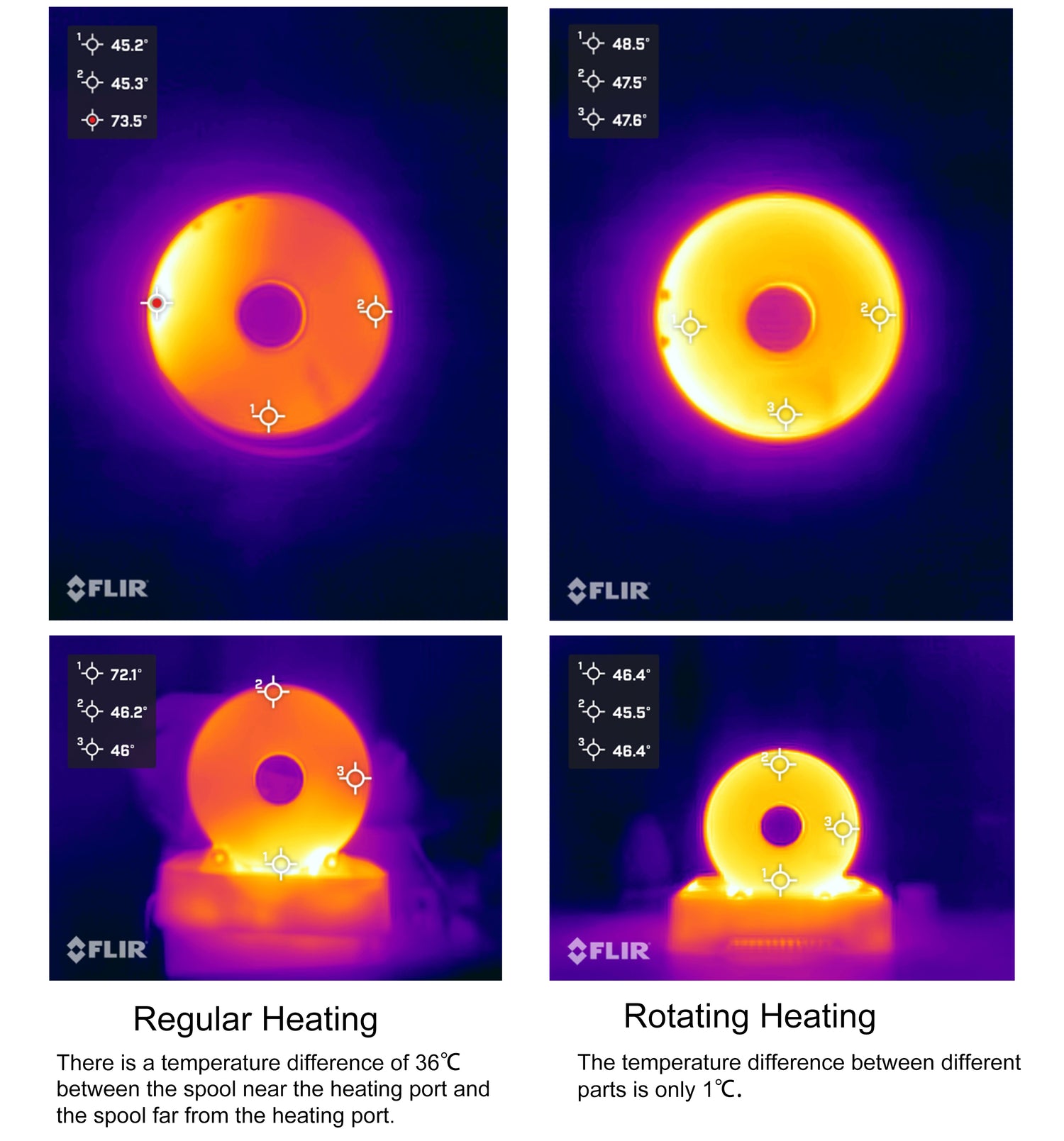

Although Polyphemus has multiple air outlets, there may still be uneven heating between the top and bottom of the drying chamber. To address this, we have added a rotating motor. You can easily activate the rotation function with a single button, truly achieving 360° automatic rotating heating.

Automatic Humidity Control Function

When heating is not required, you can activate the humidity mode and freely set the desired humidity level. The system will automatically activate the heating to regulate the internal humidity according to the set value. This ensures that the filament is always ready for printing.

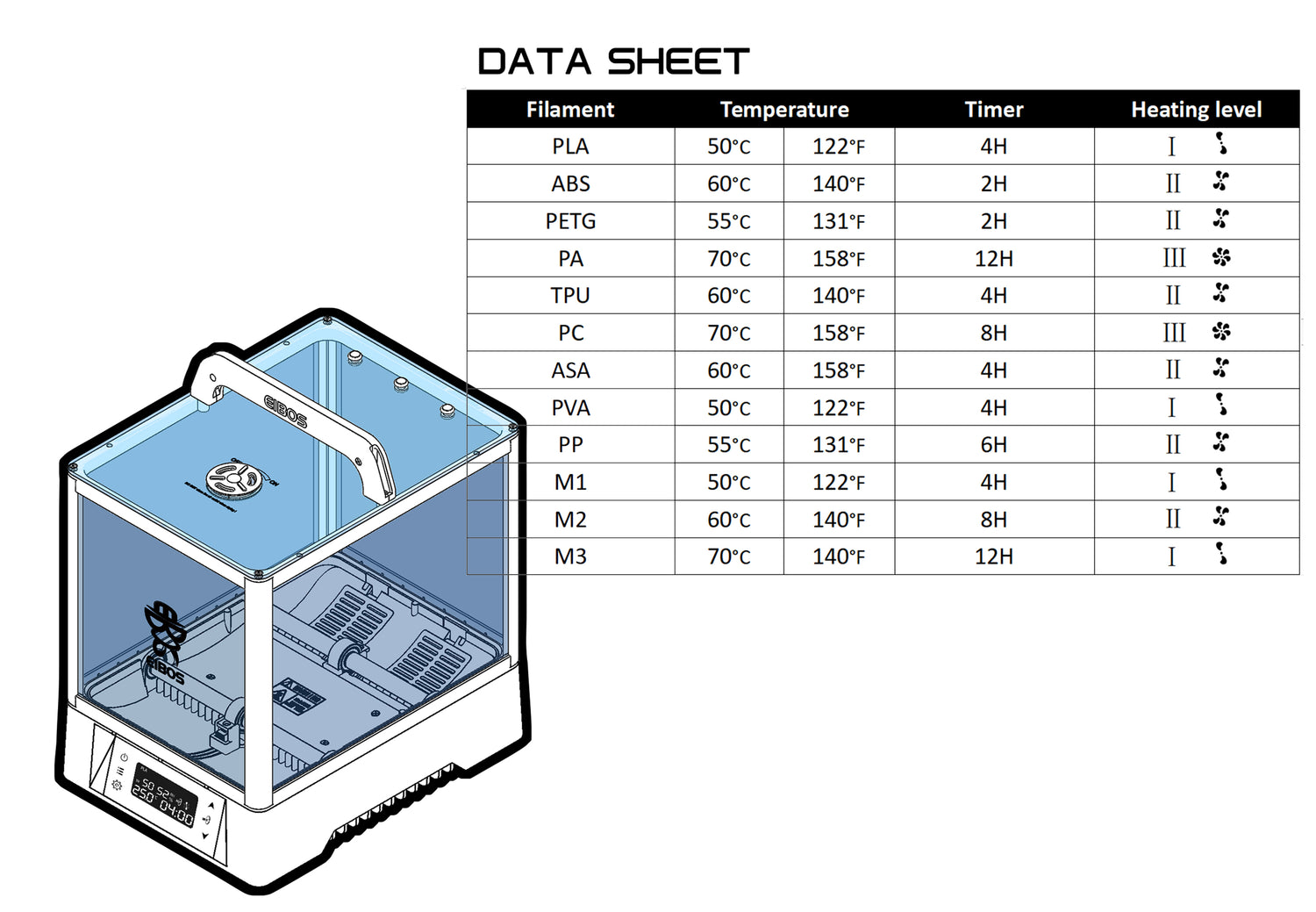

In addition, the system is equipped with 3 different heating power settings. When you need to dry high temperature materials (such as PA), you can choose the full power mode for quick drying. When drying materials with lower temperature resistance (such as PLA), you can select the low power mode for gentle drying. In the low power mode, the drying process is more gentle, and the temperature control is more precise.

The program has built in baking parameters for 9 types of materials: PLA, ABS, PA, PC, PETG, ASA, PVA, TPU, and PP. There are also 3 additional customizable material slots: M1, M2, and M3. Each material parameter includes settings for temperature, baking time, and heating power level. You can modify these parameters based on the specific requirements of your materials, and the built in system will save your settings even in the event of a power outage.

Regarding temperature, the sensors of POLYPHEMUS are placed inside the chamber. We have carefully selected multiple temperature measurement points within the box and determined the optimal sensor placement. The temperature measured at this location closely reflects the temperature of the filament. Additionally, we provide real time temperature display, allowing you to monitor the temperature of the filament at any time. The system also supports switching between Celsius (℃) and Fahrenheit (℉) for temperature display. Moreover, the system supports humidity display. In nonheating mode, you can switch to humidity mode, where the system stops heating and only displays the humidity value.