Product Background Story

During the development of our first three generations of 3D printing wire dryers, members of the team had tried to use flexible materials many times in different projects, but always encountered various technical obstacles. After several failed prints, we got together to analyze the reasons and began to conduct an in-depth evaluation of the existing extruders on the market. We found that many devices were seriously insufficient in processing flexible filaments, resulting in printing failures. This discovery made us realize that the industry urgently needs a new extruder to meet this challenge.

In October 2022, we decided to start solving this problem based on our own printing experience, which prompted us to develop Artemis, a new 3D printing extruder designed to meet these challenges. In the following months, we conducted dozens of prototype designs and tests. Finally, in November 2023, after months of hard work, Artemis was officially launched.

Artemis is compact and lightweight, reducing the weight of the entire extrusion assembly. It uses a 15:1 gear reduction ratio to provide the powerful extrusion torque required for high-speed printing. The specially designed extrusion mechanism increases the fast printing speed of flexible filaments. In addition, the transparent cover allows direct visualization of the extrusion process. Meanwhile, the customizable rotation axis adds an interactive element that enhances the user experience.

Artemis was launched with the goal of expanding the possibilities of high-speed 3D printing. It is tailored for complex materials that were previously difficult to print at higher speeds. We believe Artemis can help us further our mission by enabling efficient high-speed production across a wider range of material choices and applications!

Product Introduction Video

Highlight Key Features

-

M2 Hardened gears

-

Huge torque output

-

Reduced feed losses

-

Visible clear window

-

105g! Small size!

-

Fast flex filament extrusion

M2 HARDENED GEARS

Artemis uses precision machined M2 high alloy hardened steel gears. The gears have an outer diameter of 12 mm and undergo a thorough heat treatment process for excellent hardness and durability.

How the gears are manufactured:

First, they are quenched at 1180°C for 40 minutes to achieve a strong hardening effect. They are then tempered at 560°C for 120 minutes to refine the grain structure. This gives it a final hardness of HRC63 - much higher than other extruded gears with a hardness range of 45-55. CNC machining creates sharp tooth tips for proper meshing of filaments. At the same time, the grinding process blackens and seals the surface to prevent corrosion. With its hardened alloy core and optimized heat treatment, the final gear exhibits excellent wear resistance.

HUGE TORQUE OUTPUT

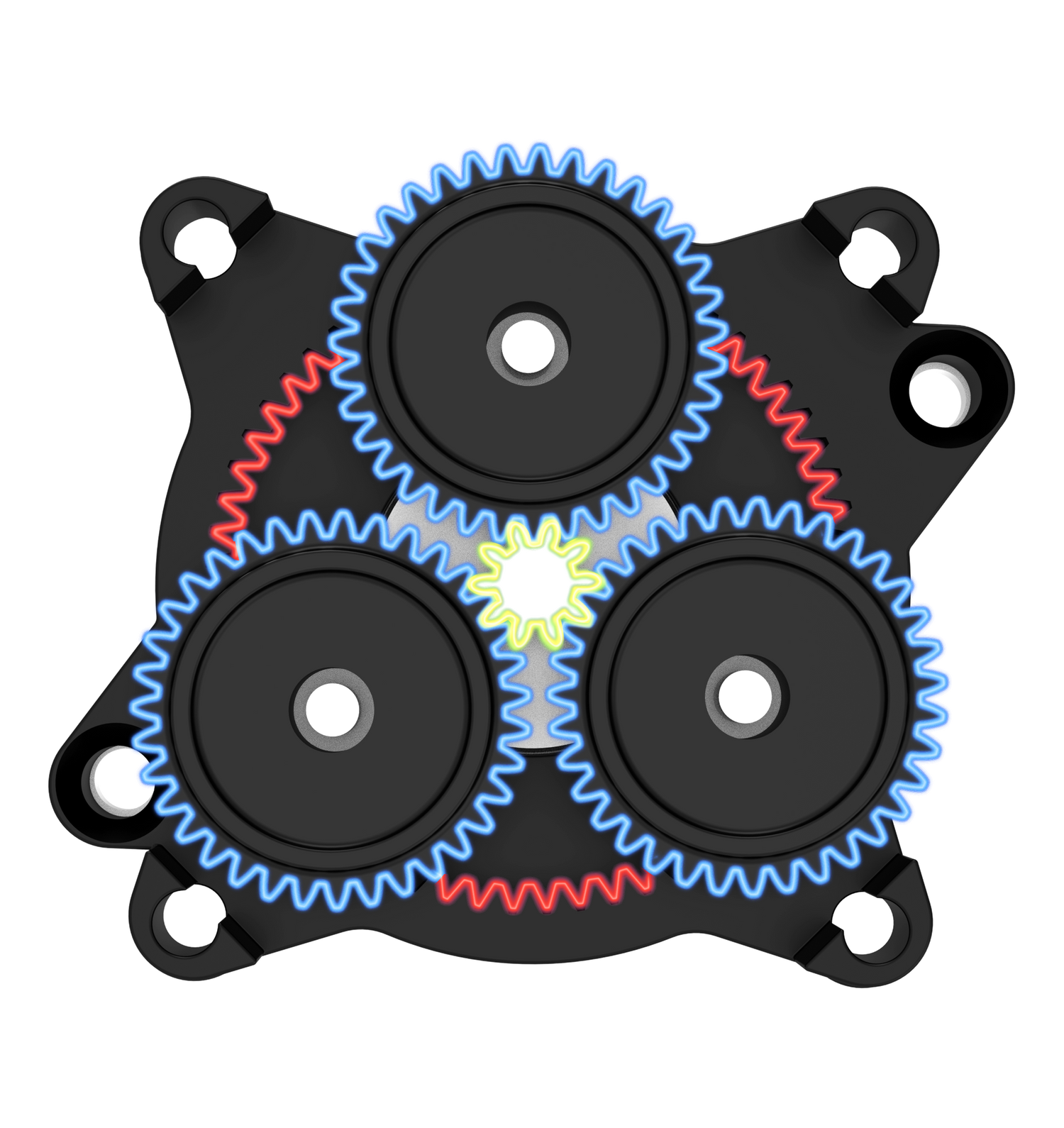

Artemis uses an optimized NW-type planetary gear train with a reduction ratio of 1:15, which can effectively increase the extrusion torque and greatly improve the torque output.

The center is a 10-tooth sun gear directly driven by a stepper motor, surrounded by 3 planetary gears, which are divided into two layers, one with 15 teeth and one with 35 teeth, and then mesh with a fixed 60-tooth ring gear that constitutes the housing.

This innovative double-linked gear transmission structure can achieve a huge torque multiplication factor. Even at higher printing speeds, Artemis can generate sample extrusion torque for continuous, large-volume deposition.

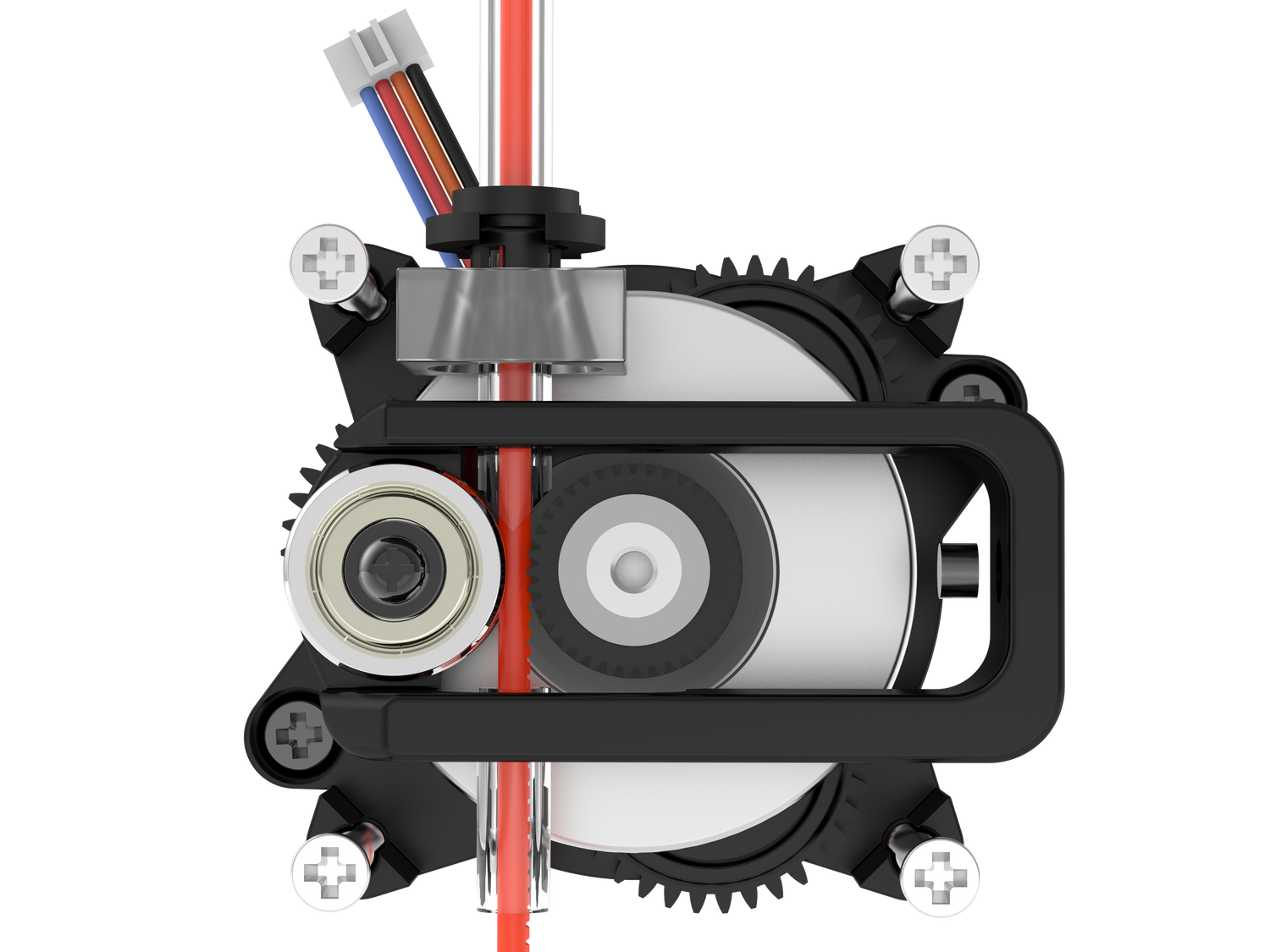

REDUCED FEED LOSSES

Artemis rethinks the filament drive mechanism for high-speed 3D printing. Conventional dual-gear extruders wear out filaments through repeated contact under rapid motion. Over time, metal and plastic debris accumulate between the pinion teeth. If not controlled, the eventual jamming can disrupt precise feeding. In contrast, Artemis uses a kinematically simpler single-gear system. Users can enjoy reliable performance for more print cycles without prematurely jamming the gears due to accumulated filament and gear debris.

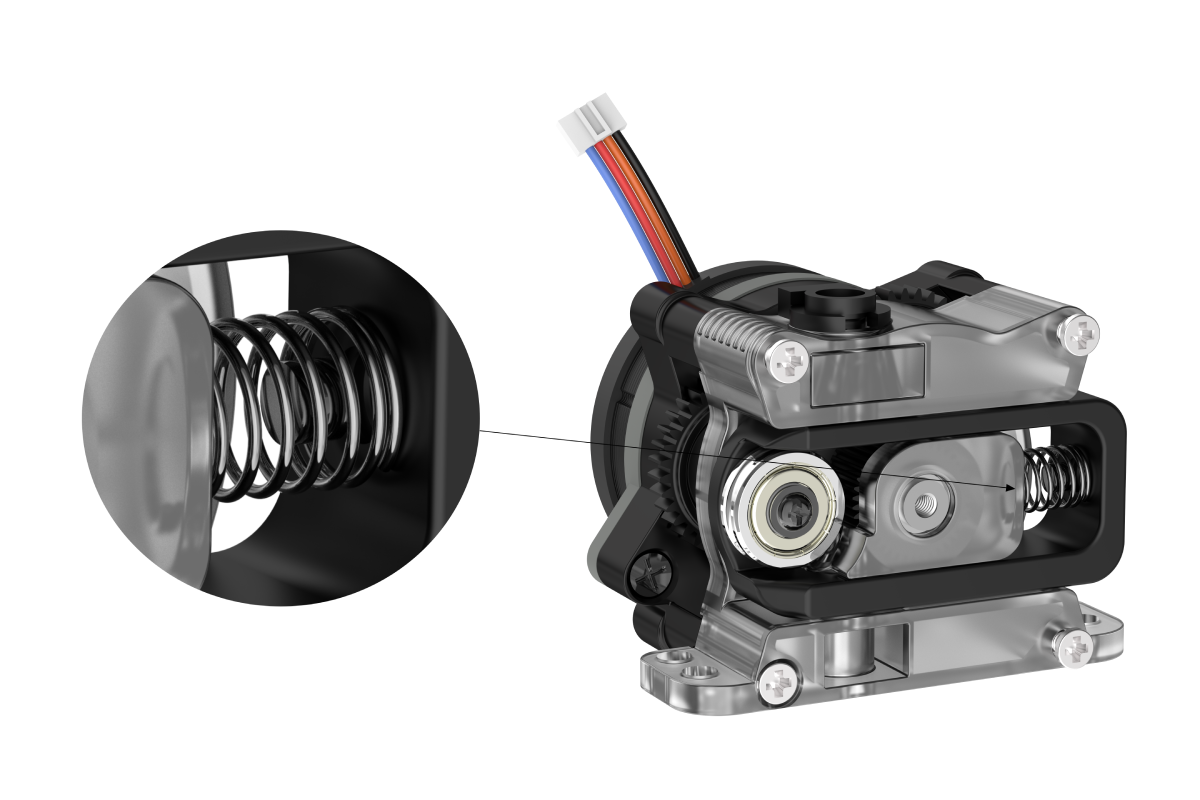

VISIBLE CLEAR WINDOW

Most extruders on the market use an opaque frame and dual gears that hide the filament feed path. Without being able to see the extrusion process, users cannot detect signs of failure in a timely manner. Artemis solves this problem with a transparent cover design. Artemis has a solid and transparent polycarbonate cover that fully exposes the meshing and movement dynamics of the filament through a single precision-cut gear. Users can now clearly see the filament in and out under the action of gear forces. Any debris accumulation that may prematurely clog the narrow-tooth extruder can be easily found and cleaned. This allows potential problems to be identified and resolved before printing is interrupted. With complete filament flow visibility, Artemis provides users with real-time process observability for preventive maintenance and maximum uptime.

105G! SMALL SIZE!

The entire design makes the entire extruder assembly very light, only 105g, this extremely low moving mass enables faster printing speeds while reducing mechanical stress on printer components during operation. The compact and lightweight Artemis can significantly reduce inertia on the X-axis.

Pairing the lightweight extruder with a high-flow hot end enables fast material flow, which helps with high-speed printing without compromising quality. By minimizing the mass on the X-axis and optimizing material throughput, Artemis can significantly improve the maximum printing speed and positioning accuracy of the entire printer.

FAST FLEX FILAMENT EXTRUSION

"30MIN A 85A BENCHY". The Artemis

extruder is able to meet the needs of relatively high-speed 3D printing with flexible filaments. It uses an elastic feed mechanism. This helps prevent problems during high-speed operation and minimizes pushing or binding that can cause jams. As a result, the Artemis is able to continuously and reliably extrude these soft materials at relatively high speeds.

Artemis:expand the possibilities of high-speed 3D printing.

It is tailored for complex materials previously difficult to print at higher speeds.