Product Background Story

In November 2020, we made a concept design of Oceanus, which was originally designed to complete the post-processing of resin 3D printing in one stop, including cleaning, drying and curing functions. With the advice of many of our loyal customers and the concept of improving the eibos product chain, we decided to put this design concept on the agenda. So we completed the first model of Oceanus in October 2021. After thousands of tests and dozens of revisions, we finalized the entire design of Oceanus in January 2022, and launched KICKSTARTER in July 2022. Within a month of the launch, we received more than 200 orders, and the amount of crowdfunding was much higher than we expected. We believe that all excellent products are based on excellent ideas of structure, and the fact that Oceanus can get a lot of support is the best proof.

Product Introduction Video

Highlight Key Features

-

Powerful cleaning

-

automatic liquid system

-

Anti-overflow design

-

Quick drying

-

All-round curing

-

Multi-layer filtration and valve protection

Powerful cleaning

Oceanus is equipped with a high-torque motor, which provides strong and stable stirring performance, ensuring that the model can be processed in all directions without dead angles during the cleaning process. Such an efficient cleaning method effectively avoids the risk of damage to model details due to incomplete cleaning. For resin models just taken out of the printer, there are usually a lot of uncured resin residues attached. Oceanus's high-performance cleaning system can quickly remove these residues, ensuring that the model surface is clean, providing the best foundation for subsequent processing

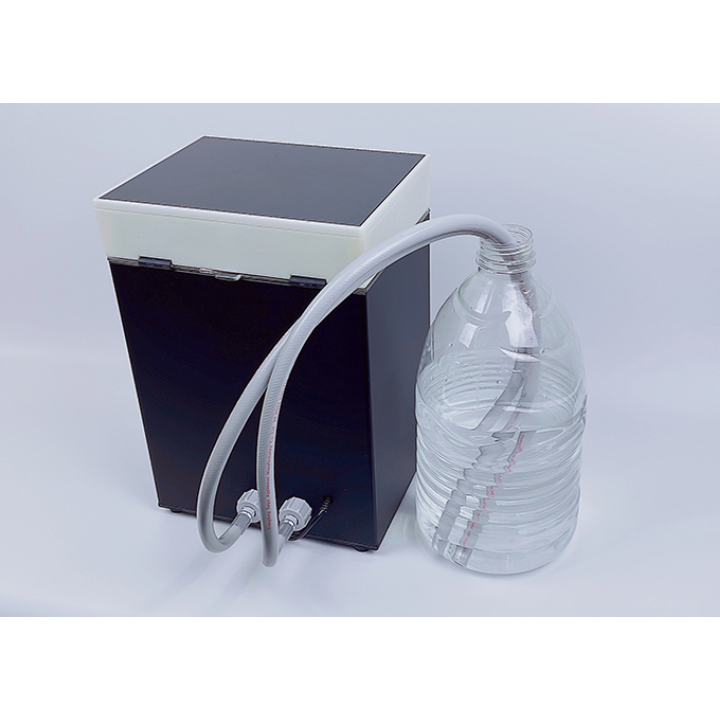

automatic liquid system

Oceanus uses a custom-designed high-power pump to achieve automatic filling and discharge of detergent (liquid), ensuring fast pumping and drainage. The automatic liquid management system greatly reduces the direct contact between operators and cleaning agents or waste liquids, improving safety and convenience.

In addition, the system effectively controls the evaporation of volatile cleaning agents such as IPA or ethanol, significantly reducing odors and avoiding contamination of the work environment. The built-in pump of the Oceanus is specially designed to smoothly handle the small particles of residue generated during the cleaning process. In terms of material selection, the pump body and pipelines are highly corrosion-resistant and suitable for chemical cleaning agents such as IPA and ethanol to ensure long-term stable operation of the equipment.

Anti-overflow design

The design of Oceanus integrates a triple anti-liquid overflow protection system to ensure a safe and reliable cleaning process:

1. Multi-stage water level sensor: The internal equipment is equipped with low, medium and high three-stage water level sensors, which can monitor the liquid level in real time according to the settings to ensure efficient operation of the equipment.

2. High liquid level Hall sensor: Located above the highest water level sensor, once the liquid level exceeds the limit, the system will immediately shut down and issue an alarm to prevent overflow.

3. Top cover physical sensor: A physical sensor is installed on the top cover of the equipment to provide additional safety for the system.

The combination design of these multiple sensors greatly improves the safety and stability of equipment operation.

Quick drying

Oceanus uses a custom-made large fan with a rotation speed of up to 7000 RPM, which provides strong airflow to effectively blow away and take away the remaining liquid on the surface of the model. Such powerful wind force not only significantly shortens the drying time, but also ensures that the model is completely dry before entering the curing stage to prevent liquid residue from affecting the curing effect. In addition, the design of this high-performance fan improves overall operating efficiency, saving time for subsequent processing and ensuring that model surfaces are clean and fully prepared.

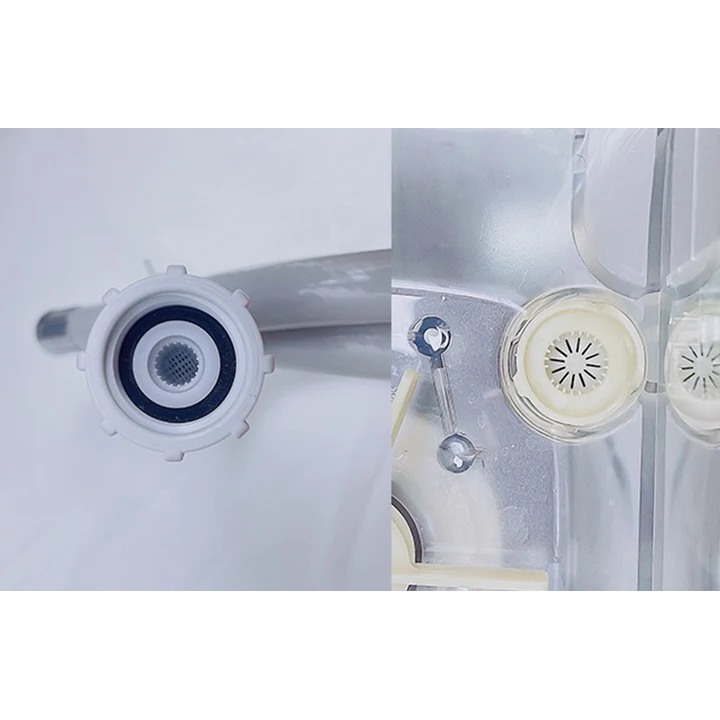

Multi-layer filtration and valve protection

Oceanus has designed filter structures and precision valves at multiple key locations to build an efficient protection system. These filters can intercept resin residues and other large particles of impurities to prevent them from entering the pump body or pipeline, ensuring the cleanliness and smooth operation of the internal system. At the same time, the precision valves work together with the filter screen to not only enhance the control of liquid flow, but also reduce the risk of pump body wear and extend the service life of the equipment.

All-round curing

96 high-efficiency UV lamp beads with a wavelength of 405nm are neatly distributed on the inner wall of the Oceanus cavity, ensuring that each lamp bead is precisely arranged to provide a uniform and strong UV light source. When running in curing mode, these UV lamp beads can cover the surface of the model 360° in all directions, ensuring that all angles can receive sufficient irradiation for fast and thorough curing. This precise lighting layout not only speeds up the curing time, but also avoids surface flaws or defects on the model caused by uneven irradiation, providing high-quality curing effects for the model.

Touch screen

Oceanus is operated by a touch panel located on the top of the device, which is simple and user-friendly. The panel is equipped with 6 independent function buttons, each corresponding to a different operation module, which supports flexible combination or individual operation to meet diverse usage needs. Users can freely set the duration of each function according to the specific situation to achieve precise control of the cleaning and curing process. The intuitive interaction of the touch panel not only improves the convenience of operation, but also provides higher flexibility and controllability, ensuring that the device can adapt to the processing requirements of different materials and models.

Oceanus: 3 in 1 automatic resin post-processing system

Simplify the complex and toxic post-processing of resin 3D printing to make resin 3D printing simpler, healthier and more reliable.

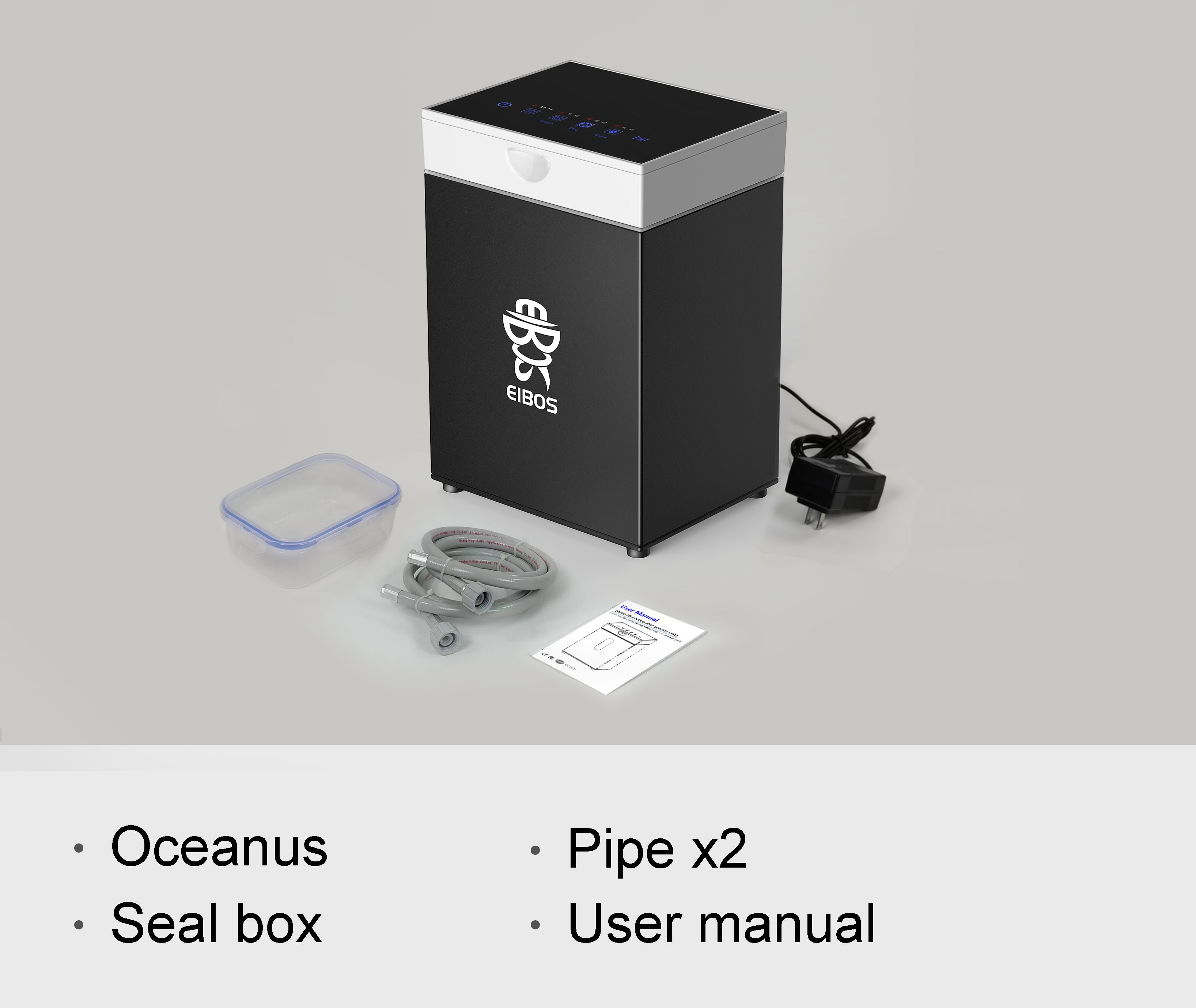

What's in box?

How to use it?