Product Background Story

In September 2017, in Australia, we found that nylon easily absorbed moisture from the air when printing, causing printing failures. Then, in December, we found the same problem again in PLA and ABS. The materials became brittle after being exposed to the air for 3 months, so we came up with the idea of making our own material dryer. In April 2019, our team moved to Shenzhen, China, where the humidity is very high. We found that the material was more likely to absorb moisture and could no longer be printed, so we made the first prototype. Between May and October, we sent our DIY machine to several friends in the 3D printing industry. They all showed great interest and wanted to see our final product. After researching for a large number of users who own FDM printers, we found that most of them needed a material dryer.

In April 2020, EIBOS began to develop a cost-effective and effective wire dryer. In the following month, we conducted thousands of research and tests before launching our first machine. In July 2020, we manufactured 30 machines and sent them to some 3D printing users or enthusiasts around the world to collect suggestions and feedback. Based on these suggestions and feedback, we developed the final product and decided to launch them on Kickstarter in September. It is the CYCLOPES in front of us. In October 2020, we completed mass production. So far, the excellent performance of CYCLOPES has enabled us to gain the support of a large number of 3D printing enthusiasts, which has prompted us to be more determined in our direction and start the research and development of the second-generation eibos wire dryer Easdry.

Product Introduction Video

Highlight Key Features

-

Extra large design

-

Fully heated

-

Easy to operate

-

Temp & time adjustable

-

MULTIPLE EXIT HOLES

-

Wide compatibility

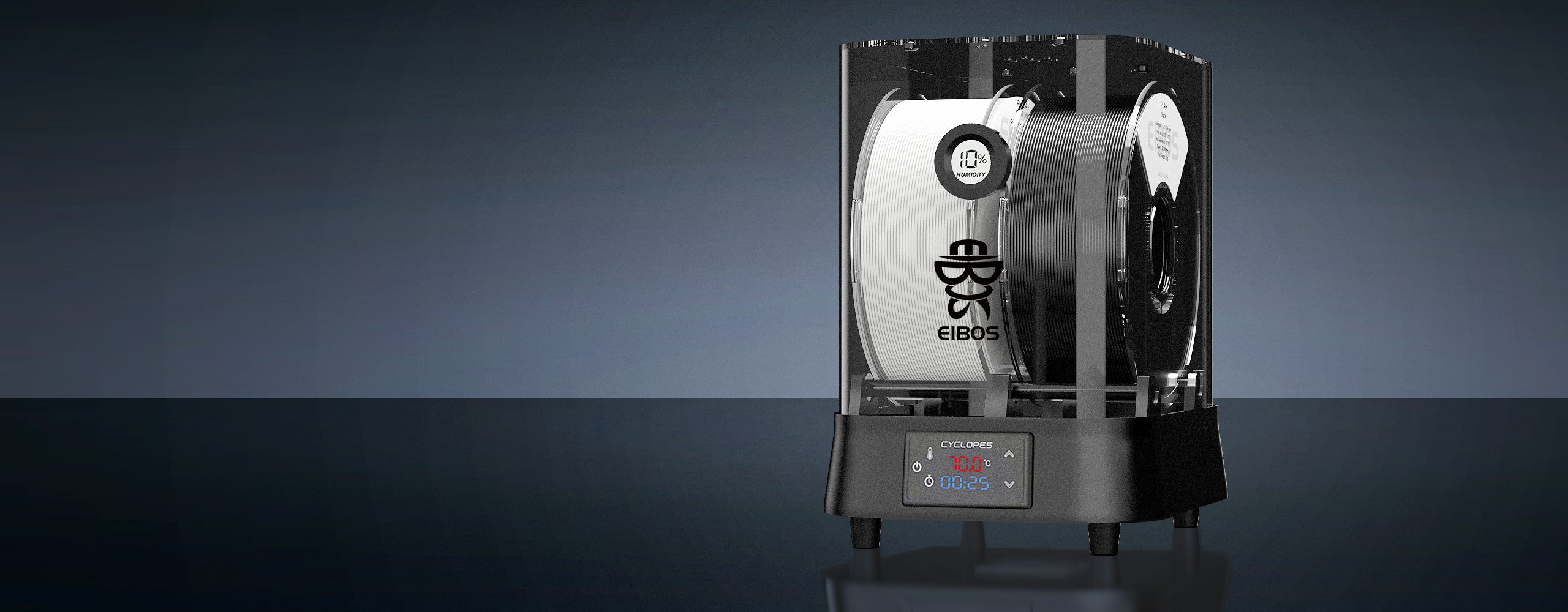

Extra large design

It has a large internal space and can accommodate four rolls of 0.5kg filament or two rolls of 1kg filament at the same time, making it very suitable for parallel use of multiple 3D printers. Its design allows drying during the printing process, effectively solving the problem of wet filaments and significantly improving printing quality and efficiency. The overall spatial design (245*305*355mm) provides greater flexibility and convenience for your 3D printing.

Fully heated

The advanced full heating method completely gets rid of the dependence on desiccants and dehumidifiers, and takes the lead in solving the problem of filament moisture. This design not only greatly improves printing efficiency, but also ensures the stability of printing quality, meeting the high standards of professional users. The built-in fan works precisely with the 100W PTC heater to evenly distribute heat, maintain the ideal temperature of the internal environment, and optimize the use of filaments. Whether it is high-precision printing or large-scale production, this device can provide users with an efficient and reliable 3D printing experience, making the creative process smoother and worry-free.

Easy to operate

The high-definition display and physical button design ensure that the interface is simple and easy to operate, suitable for all types of users to easily get started. The temperature monitoring display function provides real-time feedback on temperature changes, so that users can grasp the working status at any time. In addition, the intuitive operation interface and humanized design of the device enable novices to quickly become familiar with the use, while meeting the efficient needs of professional users.

Temp & time adjustable

Supports customizable temperature and heating time, which can be adjusted up to 70 degrees to ensure that the filament remains in an ideal dry state. Users can flexibly set the optimal temperature and heating time according to the characteristics of different materials. The timer options range from 1 minute to 24 hours, or set to unlimited mode. This personalized control not only improves the printing quality and stability of the filament, but also effectively extends its service life. Whether it is for long-term storage or temporary use, users can easily achieve efficient drying, providing reliable protection for subsequent 3D printing.

MULTIPLE EXIT HOLES

Equipped with ten filament outlet holes, six on the top, two on the front and two on the back. This design ensures that different types of filaments can be discharged smoothly from the device, avoiding entanglement or blockage during the drying process. The six filament outlet holes on the top provide excellent line channels, allowing the filament to be quickly and smoothly accessed, while the holes on the front and back enhance flexibility and facilitate users to use in different working environments. This layout not only improves operational efficiency, but also ensures the stability and reliability of the filament throughout the drying and printing process.

Wide Compatibility

Cyclopes is suitable for a variety of filament types and diameters, and is compatible with 1.75mm, 2.85mm and 3.00mm 3D filaments, including nylon, PLA, PETG, TPU, ABS, silk, carbon fiber, wood, etc. This wide compatibility enables users to easily select and use different materials to meet various printing needs. Whether printing high-strength functional parts or making exquisite works of art, Cyclopes can provide an ideal drying solution to ensure that the filament is in the best condition before use, improving the printing effect and the quality of the work.

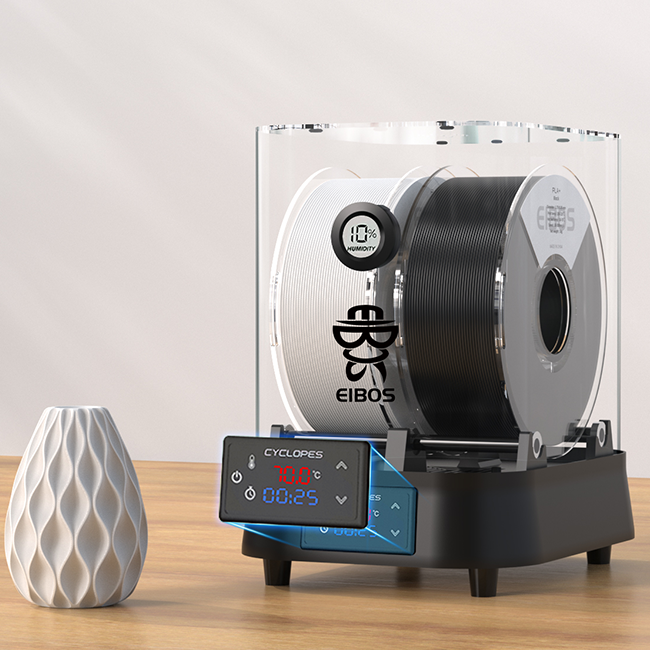

DRY YOUR FILAMENT IN CYCLOPES

Protect your filament 24 hours a day, ready for your printing inspiration at any time.

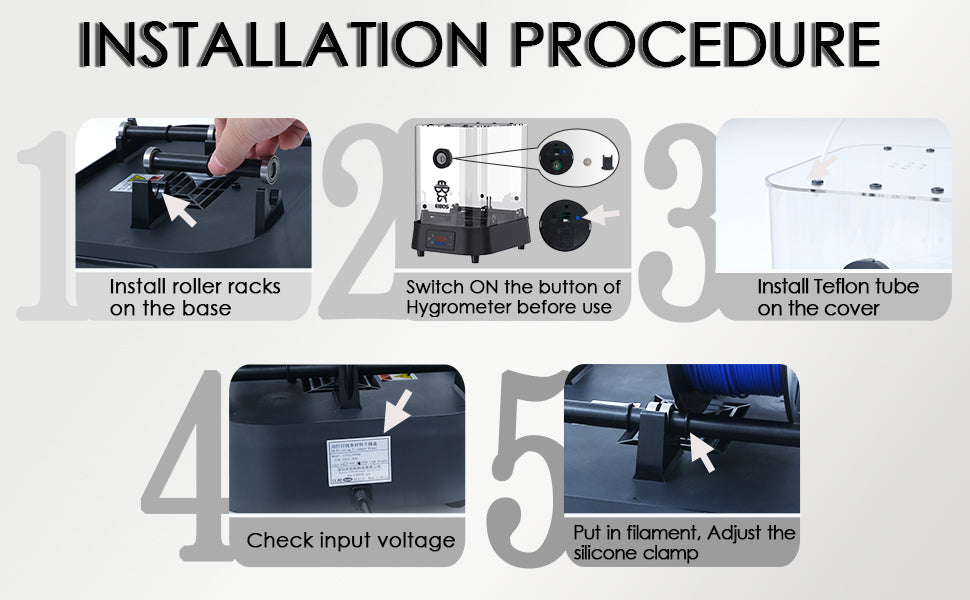

How to install?