In March 2025, Bambu Lab released the AMS 2 Pro, an upgraded version of their Automatic Material System (AMS) that introduced a built-in filament drying feature. This addition underscores the critical role that moisture control plays in 3D printing. Moisture can damage filament, leading to issues like stringing, clogging, layer shifting, and poor layer adhesion. By removing moisture, filaments can be restored to their optimal condition, ensuring smooth, high-quality prints. However, Bambu Lab has not provided an integrated solution to retrofit the original AMS with drying capabilities. In this blog, we explore three effective methods to upgrade your existing AMS with drying functionality.

1. EIBOS Tetras

The EIBOS Tetras is a specialized upgrade module designed specifically to add drying functionality to the Bambu Lab AMS. This innovative solution integrates seamlessly with the AMS, providing active drying capabilities for moisture-sensitive filaments like nylon, TPU, and PETG. The Tetras features a robust heating system and a fan to circulate warm air, ensuring consistent drying across all four filament slots. Its standout feature is the ability to dry filaments during printing, with individual temperature and time settings for each slot, offering unparalleled flexibility.

Advantages:

-

Seamless Integration: Designed specifically for the AMS, ensuring a perfect fit and easy installation.

-

Active Drying: Uses a powerful PTC heater and fan for efficient moisture removal, even during printing.

-

Customizable Settings: Allows per-slot temperature and time adjustments for precise drying tailored to different filament types.

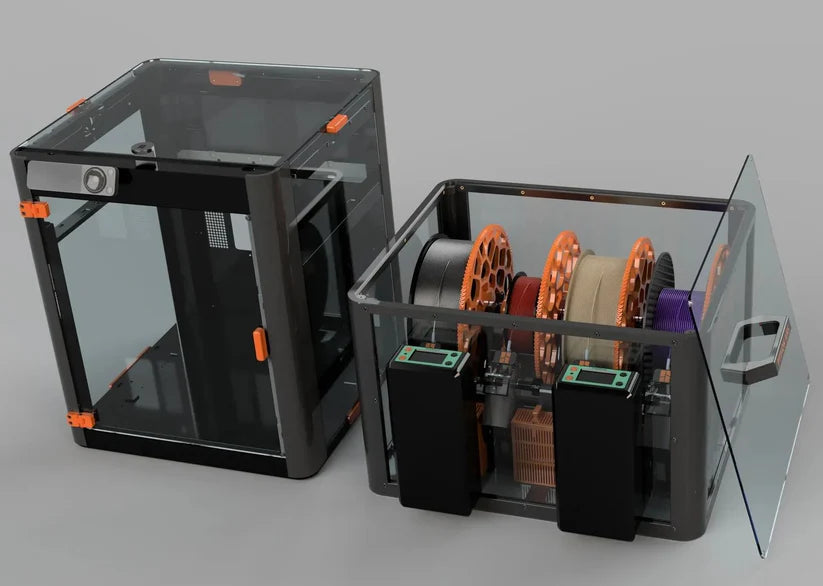

2. Python Bambu Lab AMS Upgrade

The Python Bambu Lab AMS Upgrade is a comprehensive 3D-printed kit that enhances the AMS with active drying capabilities, among other improvements. This upgrade, available from vendors like VOXELPLA, includes printed parts, screws, bearings, and optional PolyDryer attachments for active filament drying. The kit also improves spool compatibility (up to 79mm wide and 205mm in diameter) and features an upgraded PTFE loading system for easier filament handling. The Python upgrade is RFID-compatible, ensuring seamless integration with Bambu Lab’s ecosystem.

Advantages:

-

Active Drying Capability: Optional PolyDryer attachments allow for effective drying during AMS operation.

-

Enhanced Functionality: Improves spool compatibility and loading ergonomics, making it a versatile upgrade.

-

Community-Driven Design: Developed with input from the 3D printing community, ensuring practical and reliable enhancements.

Disadvantages:

-

Assembly Required: As a 3D-printed kit, it requires assembly, which may be challenging for users without technical expertise.

-

Additional Cost for Drying: PolyDryer attachments are optional and add to the overall cost.

-

Complexity: The upgrade process may involve more steps compared to simpler solutions like the Tetras.

3. Silica Dry Box for Bambu Lab AMS

Silica Dry Boxes are a popular, cost-effective solution for adding passive drying to the Bambu Lab AMS. These 3D-printed boxes, such as those remixed by designers like Thomas_63847 on Printables, fit into the front compartments of the AMS and hold approximately 100g of silica gel each. Some versions include support for hygrometers to monitor humidity levels, ensuring optimal drying conditions. These boxes are compatible with both the standard AMS and the Hydra AMS mod, offering a simple way to maintain low humidity.

Advantages:

-

Affordable: Silica gel and 3D-printed boxes are inexpensive, making this a budget-friendly option.

-

Easy to Implement: Requires minimal setup—just print the boxes, add silica gel, and place them in the AMS.

-

Effective for Storage: Maintains low humidity levels, ideal for keeping filaments dry during storage.

Disadvantages:

-

Passive Drying Only: Relies on silica gel, which is less effective at actively removing moisture from already-wet filaments compared to heated solutions.

-

Frequent Maintenance: Silica gel needs regular re-drying (e.g., in an oven or microwave), which can be time-consuming.

-

Limited Capacity: May struggle to maintain low humidity in high-humidity environments without frequent silica gel replacement.

Conclusion

Upgrading your Bambu Lab AMS with drying functionality is a practical way to enhance print quality and filament longevity, especially for moisture-sensitive materials. The EIBOS Tetras offers a premium, active drying solution with seamless integration and customizable settings, ideal for users seeking a plug-and-play experience. The Python Bambu Lab AMS Upgrade provides a versatile, community-driven solution with active drying capabilities, though it requires assembly and additional components. For budget-conscious users, Silica Dry Boxes offer a simple, passive drying method that’s easy to implement but requires more maintenance. Each option has its strengths and trade-offs, so your choice will depend on your budget, technical comfort level, and printing needs. By adopting one of these solutions, you can ensure your AMS performs at its best, delivering flawless 3D prints every time.